Commercial Roofing

Commercial Roofing West Bend & Appleton, WI

COMMERCIAL ROOFING

CAB Construction is also very active in commercial roofing for our clients in the Midwest. The four types of commercial roofing that we provide besides traditional shingles are TPO (Thermoplastic polyolefin), EPDM (ethylene propylene diene terpolymer), Modified Bitumen, and Spray Foam or SPF (spray polyurethane). We will discuss each individually and give you some of the advantages of each.

TPO ( THERMOPLASTIC POLYOLEFIN )

TPO (Thermoplastic Polyolefin) is a single-ply reflective roofing membrane made from polyprophylene and ethylene-propylene rubber polymerized together. It is typically installed in a fully adhered or mechanically attached system, allowing the white membrane to remain exposed throughout the life of the roof. TPO roofing systems are quickly growing in popularity and demand, in both residential and commercial flat roof markets. TPO can provide combined benefits of both, EPDM rubber and PVC roofs, but at a more economical cost than PVC. A TPO roofing membrane has been specifically designed to have the advantages of a rubber roof, combined with hot – air weldable seams for extra durability. TPO roofing membranes have been manufactured in the US since the early 1990’s and are now the fastest growing segment of the US single-ply roofing industry

TPO membranes take the best features from its direct competitors EPDM and PVC, while offering homeowners and businesses an innovative, energy-efficient and cost-effective roofing solution. TPO roofs are durable; resisting dirt, bacteria, algae and debris build-up. The flexibility of the membrane makes it highly resistant to tears, punctures and impact damage. This flexibility also allows for a building’s movement and setting, without compromising the roof’s performance. Moreover, a TPO roof can withstand damaging ultraviolet, ozone and chemical exposure. Hot-air welded seams are very strong, with seam strengths being as much as 3-4 times greater than EPDM adhesive and tape seams.

A TPO membrane is considered to be a cool roof and is Energy Star rated. This means that the membrane reflects the sun’s ultraviolet rays. This can significantly lower HVAC costs and make the interior temperature more comfortable during hot summer months.

EPDM ( ETHYLENE PROPYLENE DIENE TERPOLYMER )

EPDM is an extremely durable synthetic rubber roofing membrane (ethylene propylene diene terpolymer) widely used in low-slope buildings in the United States and worldwide. Its two primary ingredients, ethylene and propylene, are derived from oil and natural gas. EPDM is available in both black and white, and is sold a broad variety of widths, ranging from 7.5 feet to fifty feet, and in two thicknesses, 45 and 60 mils. EPDM can be installed either fully adhered, mechanically attached or ballasted, with the seams of the roofing system sealed with liquid adhesives or specially formulated tape.

With three different assembly methods and two membrane color choices, there is an EPDM Roof for Every Climate. Choices include black or white EPDM, and assembly methods include ballasted, fully adhered, or mechanically fastened systems. The EPDM (ethylene propylene diene terpolymer) rubber roofing membrane has been an appealing choice of the low-slope commercial roofing industry for over 40 years. EPDM continues to be a top choice of architects, roof consultants and contractors for both new construction and replacement roofing projects.

There has been over 40 years of empirical experience to show the roofing industry that EPDM has the roofing industry’s longest average service life. Some of the benefits of EPDM that contribute to its overall performance include:

- Cyclical membrane fatigue resistance

- Proven hail resistance

- High resistance to ozone, weathering and abrasion

- Flexibility in low temperatures

- Superior resistance to extreme heat and fire

- Thermal shock durability

- Ultraviolet radiation resistance

EPDM is also highly resistant to wind damage and can be designed to meet a variety of wind uplift criteria. Architects, roof consultants and contractors have come to depend on EPDM’s time tested, long-term performance. EPDM is a commercial roofing product, designed to be used in non-residential roof systems.

MODIFIED BITUMEN

Modified Bitumen is a type of roofing that is an evolution of asphalt roofing. It is made from asphalt and a variety of rubber modifiers and solvents. There are several ways of connecting pieces of this material. In a heat application process the seams are heated to melt the asphalt together and create a seal. There is also hot-mopped application, similar to how conventional built-up roofs are installed. Cold-applied adhesives and self-adhesive membranes are two of the more recent options

Modified Bitumen is a type of Membrane roofing is a type of roofing system for many types of commercial buildings. It is used to move water off the roof in an efficient manner. Membrane roofs are most commonly made from synthetic rubber, thermoplastic (PVC or similar material), or modified bitumen.

One of the longer lasting roofing options for flat roofs is a modified bitumen roof. Modified bitumen is a type of asphalt product that can be applied in a number of ways to the roof in both hot and cold temperatures. Modified bitumen roofs have a lot of advantages over other types of membrane roofing, and are often seen as the modern alternative to the built up roof.

There are several different advantages to using a bitumen roof on your building or home. Unlike some newer types of roofing, it has a long, proven track record that can be counted on. Modified bitumen roofs are one of the longer lasting types of flat roofing materials, easily lasting 20 years or more.

Regardless of how the material is applied (self-adhesive sheets, hot-mopped asphalt, or cold-applied adhesives) the seams are usually melted together which help stop leaks. Other types of membrane roofing have seams that are left open or covered with another material that can weaken over time, so the fact that a bitumen roof can be seamless is a big advantage.

Bitumen roof is also very durable. They have a high-tensile strength so they are unlikely to develop the kinds of cracks that other flat and membrane roofs are known for. They are also rated against wind, fire, and hail so they are unlikely to be damaged in the event of a storm. Included in this is usually a very long manufacturer’s warranty that can help to guarantee the roof’s longevity.

One of the disadvantages of a modified bitumen roof is that they are usually black in color, which can absorb rather than reflect heat. if proper insulation is not used with it, this absorption of heat can lead to heating of the building below.

Bitumen roofing is also available in 1, 2, or 3-ply. The 1-ply material is not durable, and if used can pose certain problems such as breaking down prematurely, while the 2 and 3-ply material roofs cost significantly more to install, which can make this one of the most costly types of flat roofing products around.

Granules need to be included as part of the installation process to help protect the roof from the sun. If they are not included, this can further raise the temperature of the building or damage the roof. Unfortunately, not all types of bitumen roofs include granules as part of the installation process.

Finally, if your roof is likely to hold a lot of water or to gather puddles of standing water after rainstorms, this can prematurely age and damage the bitumen roof.

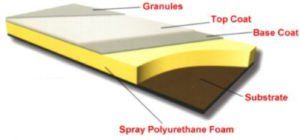

SPRAY FOAM OR SPF ( SPRAY POLYURETHANE )

Spray Polyurethane Foam (SPF) is a form of plastic that goes from liquid to solid in a matter of seconds, increasing in volume approximately 30x as it dries. It is one of the most cost-effective and sustainable roofing, insulation and waterproofing system available today. Spray Polyurethane Foam (SPF) is the only roofing material that has no seams. Foam roofing bonds around roof penetrations such as pipes, vents and edges forming an impenetrable wedge, leaving these penetrations safe from water leaks.

SPF roofs should not only save energy, but also never wear out. As long as the upper coating layer is maintained, the roof will last the life of the building.

SPF roofs last indefinitely and hold their insulation value forever. Spray Polyurethane Foam is by far the Best Insulator you can buy. Closed-cell SPF stands alone as the only insulating material that does not soak up water. They can withstand extraordinary weather events like heavy winds, hurricanes, and even tornadoes.

Advantages:

- Can be applied rapidly with little or no disruption to the facilities.

- Requires fewer people to apply – which reduces the likelihood of accidents.

- Eliminates the need for multiple levels of roofing required by conventional systems.

- Conforms to all roof shapes and types.

- Can be applied directly over asphalt, shingles, built-up roofs, clay tile, concrete, metal and wood.

- Produces energy savings of 30% compared to alternative roofing systems.

- Evens out roof surfaces so there are no dips where water can collect.

- Self-flashing and seamless – therefore no leaks.

- Is highly resistant to chemical attack.

- Requires minimal upkeep to remain under warranty.

- Lasts forever if properly maintained.

Disadvantages:

- Limited Installation Window – you have to have the right the right temperature, humidity and wind conditions to install an SPF roof.

- Surface Preparation Very Important – in order to adhere correctly all loose gravel, metal or bits of old roofing must be completely removed before spraying.

FREE ROOF REPLACEMENT INSPECTIONS

A roof is a multi-layered system of protection of your home, and the integrity of a r oof is crucial to the safety of a building and its inhabitants

Visit

Wisconsin Locations

Appleton, WI

400 S Linwood Ave

Appleton, WI 54914

Phone: (844) 961-5050

Kewaskum, WI

Phone: (844) 961-5050

Kewaskum, WI

919 N River Rd,

West Bend WI 53090

Phone: 844-781-7117

Tennessee Locations:

415 Church St

Suite 1506

Nashville, TN 37201

Phone: 844-781-7117

Visit

Missouri Locations:

Jefferson City, MO

2713B Industrial Drive

Jefferson City, MO 65109

Phone: 844-781-7117

Phone: 844-781-7117

Independence, MO

1600 South Noland Road

Independence, MO 64055

Phone: 844-781-7117

We are also licensed in Illinois

104.018189

105.008436]

Kentucky Location:

1890 Star Shoot Pkwy

Lexington, KY 40509-4566

© 2024

All Rights Reserved | CAB CONSTRUCTION LLC | Privacy Policy